Printed Laminated Pouches

Printed Laminated Pouches Specification

- Tensile Strength

- High, suitable for packaging applications

- Length

- Customizable, typically ranges from 50 mm to 500 mm

- Width

- Customizable, typically ranges from 50 mm to 400 mm

- Surface Handling

- Gravure Printing, Matte or Glossy Finish

- Thickness

- 50 to 200 microns (customized as per requirement)

- Feature

- Moisture Proof, Leak Proof, Good Printability, Durable

- Material

- Multi-layered Laminates (PET, LDPE, BOPP, Aluminum Foil, etc.)

- Processing Type

- Laminated

- Hardness

- Soft / Flexible

- Transparency

- Transparent, Opaque options available

- Color

- Multicolor, Customizable as per design

- Bag Type

- Stand Up, Side Gusset, Three Side Seal, Center Seal

- Printing Type

- Rotogravure up to 9 colors

- Storage Condition

- Ambient

- Waterproof

- Yes

- MOQ

- As per order requirement

- Applications

- Food Packaging, Pharma, Cosmetics, Chemicals, Snacks, etc.

- Closure Type

- Heat Sealed, Zipper, or Slider Options Available

- Shelf Life

- Up to 24 months depending on contents

Printed Laminated Pouches Trade Information

- Minimum Order Quantity

- 300 Kilograms

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- bags

- Main Domestic Market

- All India

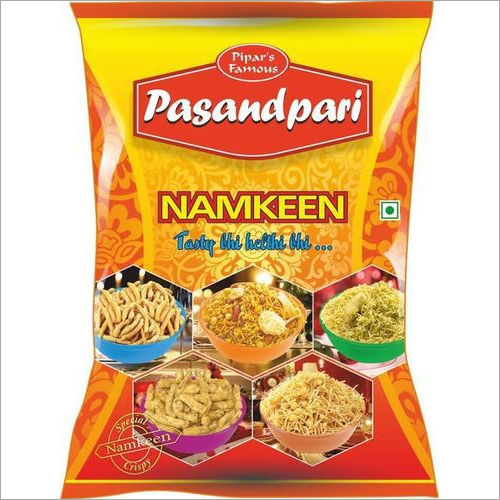

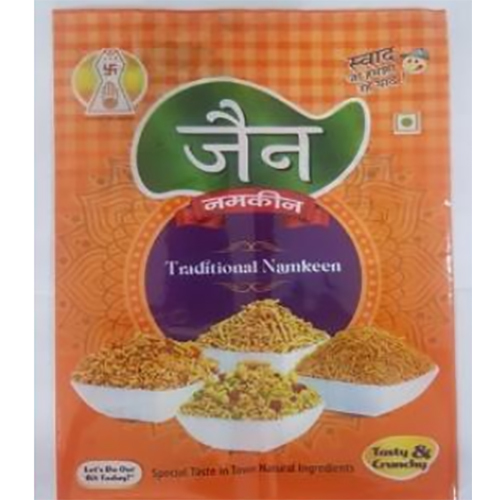

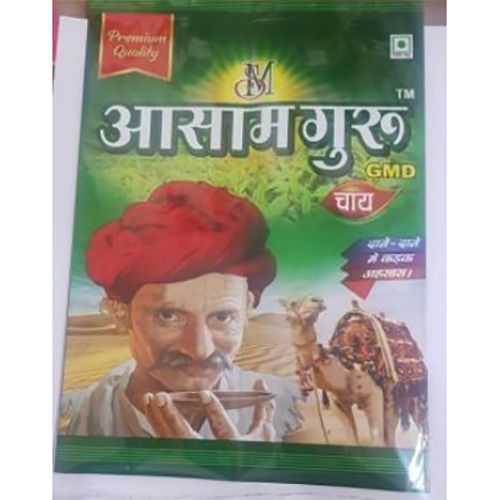

About Printed Laminated Pouches

Avail from us wide assortment of PP Laminated Pouch that is made up of best grade raw component. These pouches are widely used in various industries for packaging of sweets, snacks and different other food items. These pouches are highly esteemed for their clarity, high tensile strength, and attention-grabbing print and durability that can keep packed food safe for a long time. Moreover, our offered PP Laminated Pouch is highly cost-effective and is available in diverse designs, colours and specified dimensions.

| Pattern | Printed |

| Is It Laminated | Laminated |

| Packaging Type | Bundle |

| Layer | 2 |

| Color | Multicolor |

| Material | Plastic |

Customizable Packaging for Diverse Industries

Our laminated pouches are engineered to meet the distinct needs of food, pharma, cosmetics, and chemical sectors. With customizable sizes, thicknesses, and print options, you can design packaging that perfectly aligns with your brand, assures product safety, and optimizes shelf appeal.

Advanced Printing & Finishing Options

Utilizing rotogravure printing technology, we can produce high-quality graphics with up to 9 colors. Choose between matte or glossy surface finishes to enhance your products visual impact and appeal to your target customers.

Superior Protection and Durability

Designed with multi-layered laminates and customized thickness (50200 microns), our pouches offer exceptional strength, moisture-proofing, and leak resistance. This ensures your products remain secure, fresh, and protected throughout their shelf life, which can extend up to 24 months.

FAQs of Printed Laminated Pouches:

Q: How can I customize the size and thickness of the laminated pouches for my product?

A: You can specify the required length (50 mm to 500 mm) and width (50 mm to 400 mm), as well as the thickness (50 to 200 microns), during the order process. Both size and thickness are customizable, ensuring the pouches meet the precise needs of your application and provide optimal protection.Q: What closure options are available, and how do I select the best one for my packaging?

A: Closure types include heat-sealed, zipper, and slider. The choice depends on the product type and user convenience requirements. Zipper and slider closures are ideal for resealable packaging, while heat sealing offers a tamper-evident solution for products needing extra security.Q: When should I use these pouches for ambient storage, and what is the typical shelf life?

A: These pouches are designed for products that require ambient (room temperature) storage. The shelf life can be up to 24 months depending on the product inside and storage conditions, owing to the moisture-proof and leak-proof properties of the multi-layered laminates.Q: What is the printing process used, and what benefits does it offer?

A: We utilize rotogravure printing technology, capable of delivering vivid and precise graphics in up to 9 colors. This process allows for high-resolution images and logos, enhancing product branding and shelf appeal while ensuring good printability on both matte and glossy finishes.Q: Where are these pouches typically used?

A: Our printed laminated pouches are commonly used in food packaging, pharmaceuticals, cosmetics, chemicals, and snacks. Their protective features and customizable appearance make them suitable for a wide range of retail and industrial packaging needs.Q: What materials are used in the construction of these pouches, and how do they benefit product longevity?

A: The pouches are made from multi-layered laminates such as PET, LDPE, BOPP, and aluminum foil. These materials enhance puncture resistance, barrier protection against moisture and oxygen, and overall durability, extending the shelf life and ensuring the safety of packaged goods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laminated Pouches Category

Gujet pouch

Price 200 INR / Kilograms

Minimum Order Quantity : 300 Kilograms

Material : PP

Surface Handling : Digital Printing

Color : Multicolour

Feature : Waterproof, Moisture Proof, EcoFriendly

Printed Pouches

Price 160 INR / Kilograms

Minimum Order Quantity : 300 Kilograms

Material : Laminated Material

Surface Handling : Gravure Printing

Center seal

Price 200 INR / Kilograms

Minimum Order Quantity : 300 Kilograms

Material : PP

Surface Handling : Digital Printing

Color : Multicolour

Feature : Waterproof, Moisture Proof, EcoFriendly

Center sealing

Price 210 INR / Kilograms

Minimum Order Quantity : 300 Kilograms

Material : PP

Surface Handling : Digital Printing, Color Printing

Color : Multicolour

Feature : Waterproof, Moisture Proof, Glossy, EcoFriendly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free